PE/PP foam is a type of foam material made from a combination of polyethylene (PE) and polypropylene (PP) plastics. It is known for its lightweight, shock-absorbing, and cushioning properties, making it ideal for use in a wide range of applications such as packaging, automotive, construction, and sports equipment.

PE/PP foam is produced by a process called extrusion, which involves melting and blending the PE and PP resins together to create a foam material with a closed-cell structure. The closed-cell structure makes the foam material resistant to moisture, chemicals, and mold growth.

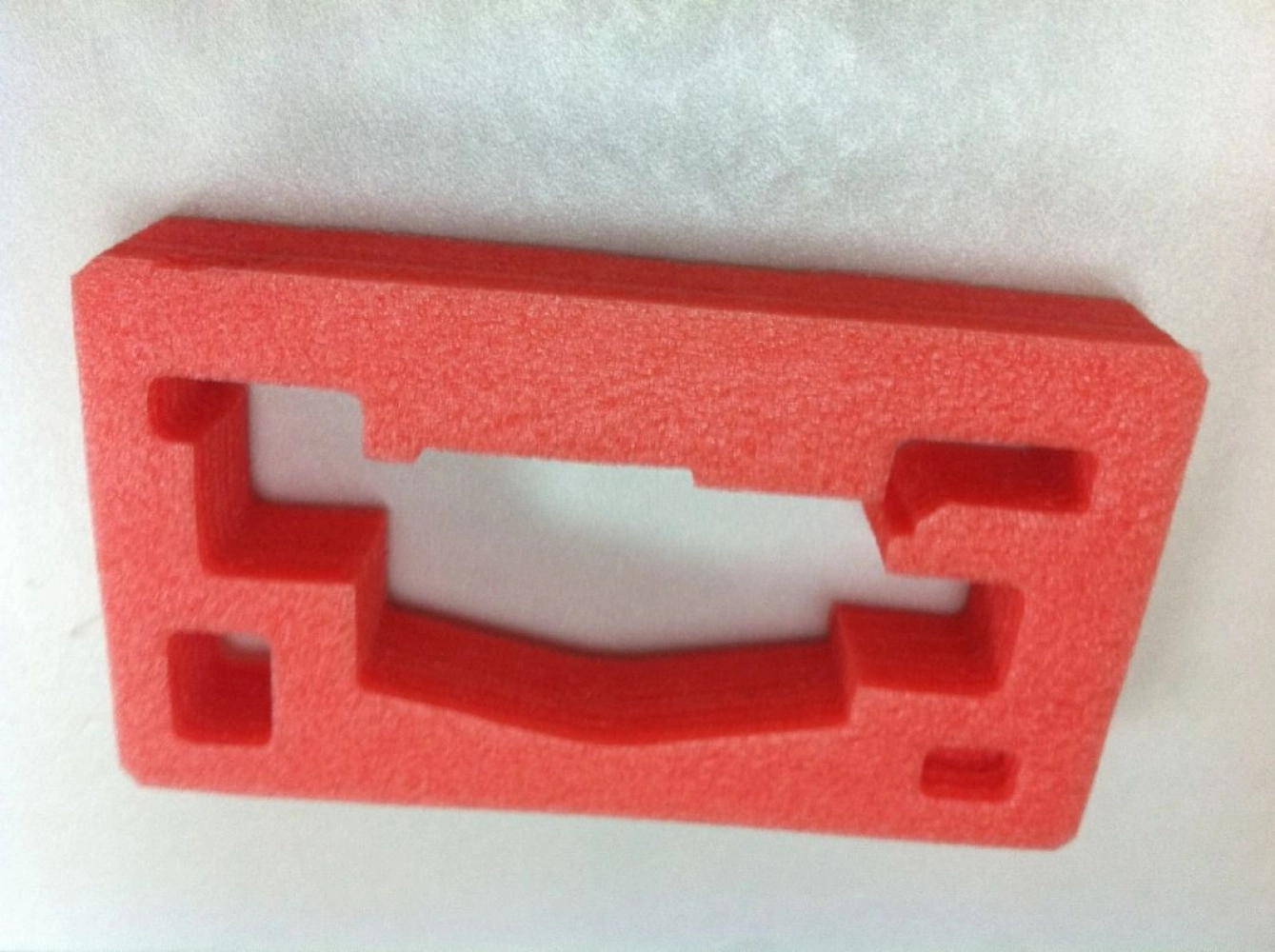

PE/PP foam is commonly used as a packaging material for fragile or delicate items such as electronics, glassware, and artwork. It is also used as a cushioning material in automotive parts, furniture, and sports equipment such as helmets and pads. In the construction industry, PE/PP foam is used as an insulation material for walls, roofs, and floors.

One of the advantages of PE/PP foam is that it is recyclable, and some manufacturers have developed methods for recycling the material into new products. This makes it a more sustainable choice than other types of foam materials, such as polystyrene foam.

Inquiry - PE / PP Foam